Services

General

Leominster Micro Welding can accommodate a wide range of customer’s Laser and micro TIG welding needs. Versatile technology allows for the welding of large molds up to 2 tons, or small intricate parts. With a diligent workforce, LMW can produce hundreds of parts in short run production, or a customer’s one of a kind job. An expertise in metallurgy allows for welding an extensive range in materials including:

- Mild Steel and Stainless Steels including; 308SS, 316SS, 410SS, 420SS

- Tool Steels – A2, M2, D2, P20, MOD-P20, H13, S7

- Non-Ferrous Alloys – Beryllium, Aluminum

- Specialty Alloys – Nickel, Inconel,

- Precious Metals – Gold, Silver

If the type of metal a job requires is not listed, call or email for an inquiry

Laser Welding

LMW proudly uses Laser technology. Currently utilizing a 300 Watt and the newly added 450F Fiber laser. The open-air and ergonomically sound design allows for versatility on complex and intricate jobs. Precise weld control and low heat input yields the least distortion resulting in little to no heat-affected zone (HAZ). Exact weld deposits minimize both machining and downtime.

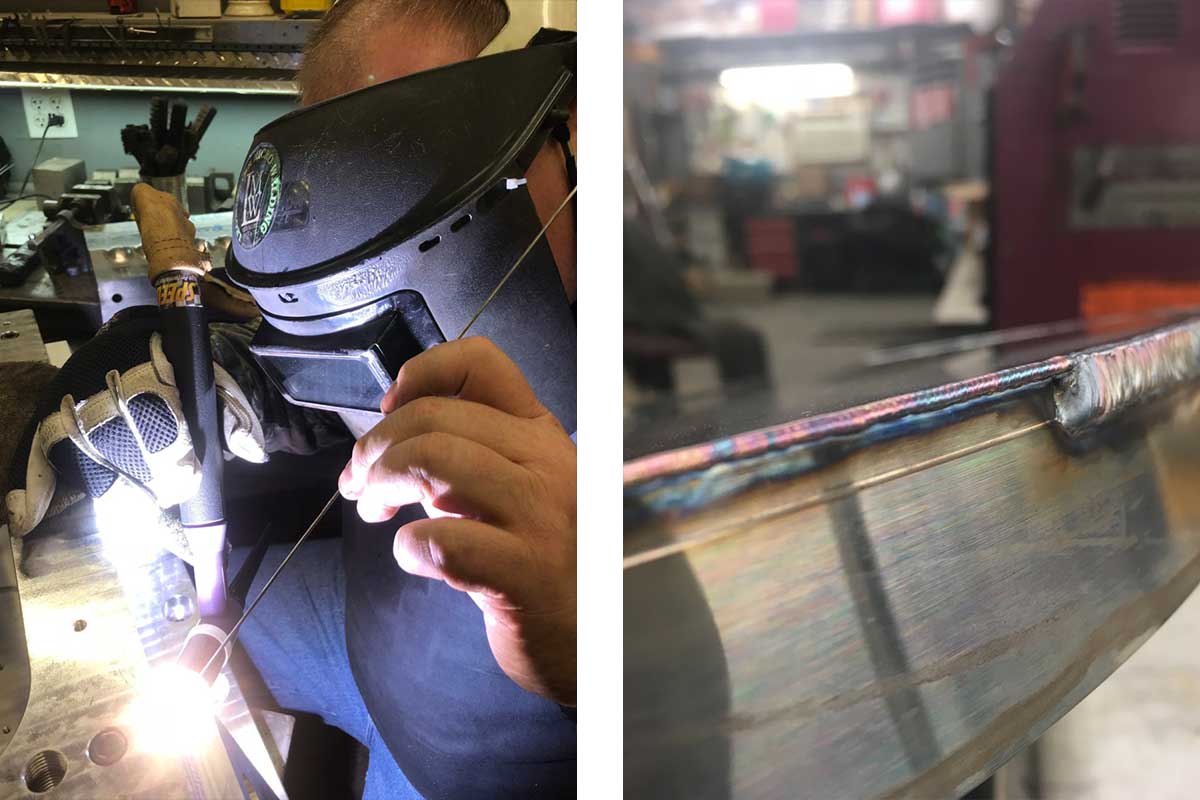

Micro TIG Welding

With two micro welders on site, LMW can accommodate all TIG welding needs. The company was founded as a TIG operation and a wide range of skill allows for welding of parts usually deemed un-weldable. All parts are pre and post heated as necessary to ensure the quality and integrity of welds.